What are the requirements of rubber tube in custom-made

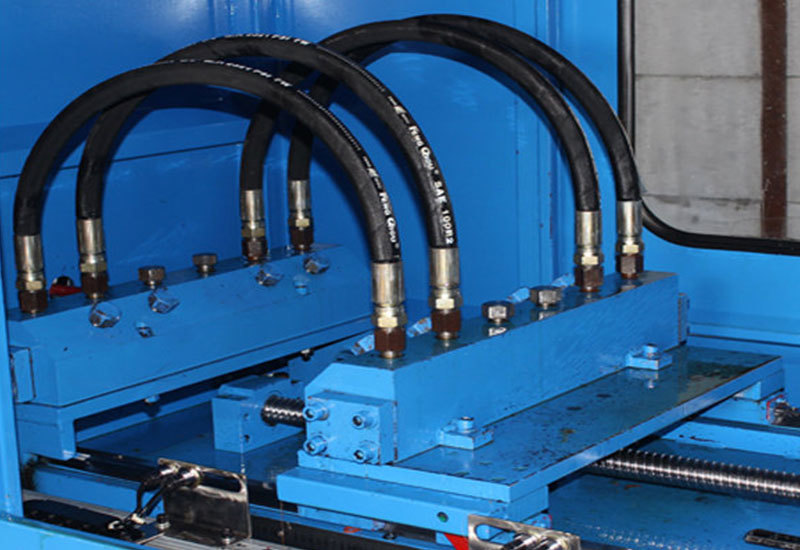

Due to the complex variety of rubber tubes, diverse structures, and different use conditions, the service life of rubber tubes is not only determined by the quality, but also by the correct use and maintenance. Therefore, even if the rubber tube has high quality, if it cannot be used and maintained correctly, it will seriously affect its quality and life, so some matters need to be paid attention to when using it. Rubber hose and hose assembly can only be used to transport the designed material, otherwise it will reduce the service life or failure. Correct use of the length of the rubber tube, the length of the rubber tube changes under high pressure (-4%- 2%) and the length changes caused by mechanical movement. The rubber hose and hose assembly shall not be used under the pressure of the design working pressure (including impact pressure). Under normal conditions, the temperature of the medium conveyed by the rubber hose and hose assembly is -40 ℃- 120 ℃, otherwise the service life will be reduced. The rubber hose and hose assembly shall not be used with a smaller bending radius than the hose, so as to avoid bending near the pipe joint, otherwise it will hinder the hydraulic pressure transmission and conveying materials or damage the rubber hose assembly.

The role of rubber tube is mainly used in steel mills and other harsh environments with high working environment temperature. So what are the requirements at the time of it? Next by our staff to give you a brief introduction to the relevant knowledge of the rubber tube. The rubber hose should pay attention to the working pressure of the use environment, select the corresponding rubber hose, and determine the length of the hydraulic hose assembly. The length should be moderate, not short feet or too long. Armoring should be carried out after determining the length. Asbestos should be added in case of high temperature in the external environment to play a flame retardant role. Generally, a layer of asbestos should be added, and two layers of asbestos should be added in case of high temperature.

Recommend News

Congratulations on the official launch of the website

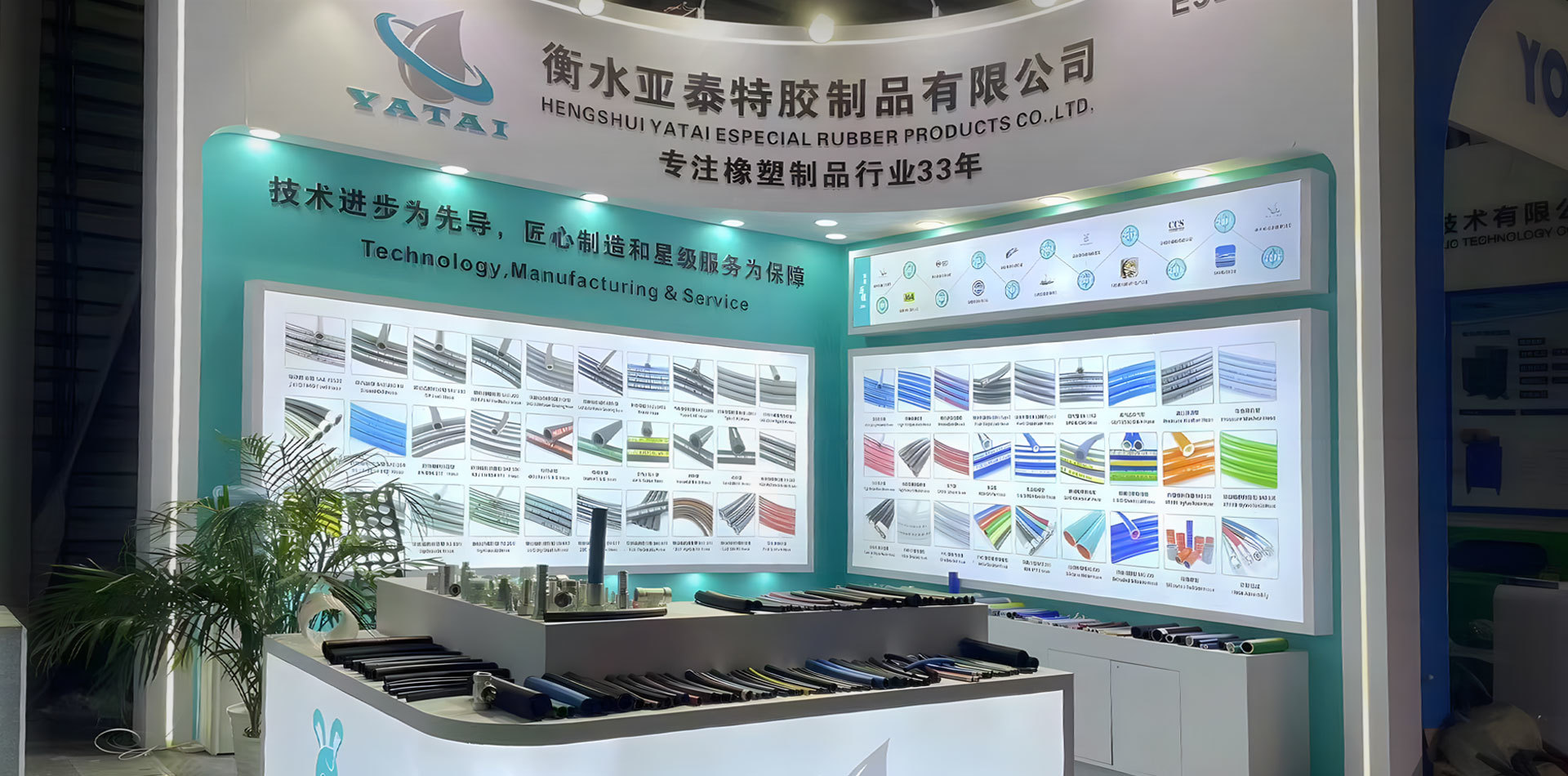

Hengshui yatai rubber products co., ltd (Hengshui yatai Especial rubber Products co., ltd.) was founded in 2001 and is a professional manufacturer of high-performance rubber hoses.

Performance and Application of High Temperature Steam Hose

In modern industrial production, high temperature steam hose is a very important equipment and has a wide range of applications. It can not only transport high-temperature steam, but also withstand high pressure and wear resistance, so it has been widely used in many industrial sites.