Reasons for Shorter Life of High Pressure Hose for Suction and Drainage

1, by frequent, intense pressure impact, suction drainage hose burst, generally not due to static pressure is too large, but with the intensity of the pressure impact and the number. During the operation of construction machinery, the oil pipe will repeatedly rise or fall suddenly, which constitutes a frequent pressure shock, resulting in increased damage to the oil seal of each part, foaming and cracking of the suction and drainage hose, and loosening and leakage of pipe joints. Therefore, during operation, the valve stem can not be pulled too hard, to be gentle.

2, the use of oil temperature is too high. During the operation of construction machinery, the hydraulic system heats up the oil due to power loss, and the influence of the outside air temperature (in summer) can cause the oil temperature to rise sharply. The higher the oil use temperature, the easier the rubber is to age, the elasticity becomes poor, and the sealing performance decreases, and the suction and drainage hose will quickly burst. Therefore, in the operation, when the temperature rise of the hydraulic system is too high or too fast, the cause should be found out in time and eliminated; when the summer operation is continuous operation, cooling measures should be taken.

3. The installation of suction and drainage high-pressure hose is unreasonable. When replacing the suction and drainage hose, the length, number of steel wire layers, joint shape and size of the suction and drainage hose should be reasonable, and the bending degree of the suction and drainage hose should be minimized. When tightening the joint nut, do not distort the suction and drainage hose. Excessive bending and distortion will greatly reduce the service life of the suction and drainage hose. Measures should be taken for some parts prone to friction, the suction and drainage hose bursts due to abrasion.

The next one:

Recommend News

Congratulations on the official launch of the website

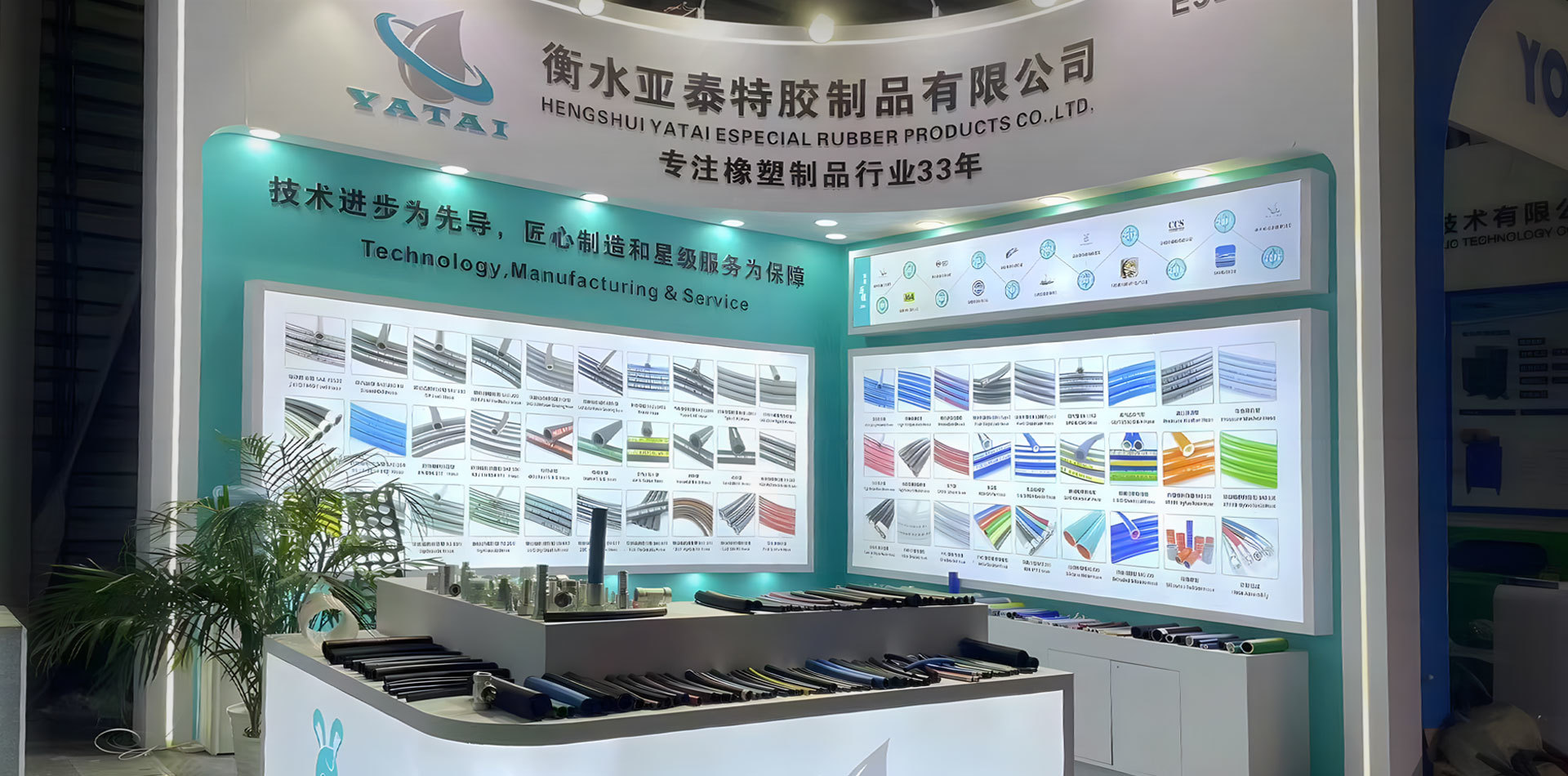

Hengshui yatai rubber products co., ltd (Hengshui yatai Especial rubber Products co., ltd.) was founded in 2001 and is a professional manufacturer of high-performance rubber hoses.

Performance and Application of High Temperature Steam Hose

In modern industrial production, high temperature steam hose is a very important equipment and has a wide range of applications. It can not only transport high-temperature steam, but also withstand high pressure and wear resistance, so it has been widely used in many industrial sites.