High pressure rubber tube working pressure need to pay attention to what matters

When installing the high-pressure rubber tube, try to avoid heat sources and stay away from the performance of the engine exhaust pipe. At this time, devices such as casing or protective screen can be used to avoid thermal deterioration of the hose. Where the high-pressure rubber tube crosses or may rub against the mechanical surface during work, protective devices such as hose clamps or springs should be applied to avoid damage to the outer layer of the high-pressure rubber tube. High pressure rubber tube bending, the bending radius should not be too small, should be greater than 9 times the outer diameter. The connection between the high-pressure rubber pipe and the joint shall have a straight line section 2 times larger than the outer diameter of the pipe. When installing the high-pressure rubber tube, avoid being in a tight state. Even if there is no relative movement at both ends of the hose, the hose should be kept loose. The tensioned hose will expand under pressure. Do not twist the high-pressure rubber tube during installation. The high-pressure rubber tube may be slightly twisted to lower it and loosen the joint. When assembling, the joint should be tightened on the hose instead of tightening the hose on the joint.

Due to the high pressure rubber tube varieties complex, diverse structure, coupled with the use of different conditions, so the length of service life of high pressure rubber tube, depends on the quality is good or bad, but also depends on the correct use and maintenance. Therefore, even if the high-pressure rubber tube has high quality, if it cannot be used and maintained correctly, it will seriously affect its quality and life, so some matters need to be paid attention to when using it. High pressure rubber hose and hose assembly can only be used to transport the designed material, otherwise it will reduce the service life or failure. Proper use of the length of the high-pressure rubber tube, the length of the high-pressure rubber tube changes under high pressure (-4%- 2%) and the length changes caused by mechanical movement. The high-pressure rubber hose and hose assembly shall not be used under the pressure of the design working pressure (including impact pressure). Under normal conditions, the temperature of the medium conveyed by the high-pressure rubber hose and hose assembly should not be higher than -40 ℃- 120 ℃, otherwise the service life will be reduced. The high-pressure rubber hose and hose assembly shall not be used at a smaller bending radius than the hose to avoid bending near the pipe joint, otherwise it will hinder the hydraulic transmission and conveying of materials or damage the high-pressure rubber hose assembly.

The next one:

Recommend News

Congratulations on the official launch of the website

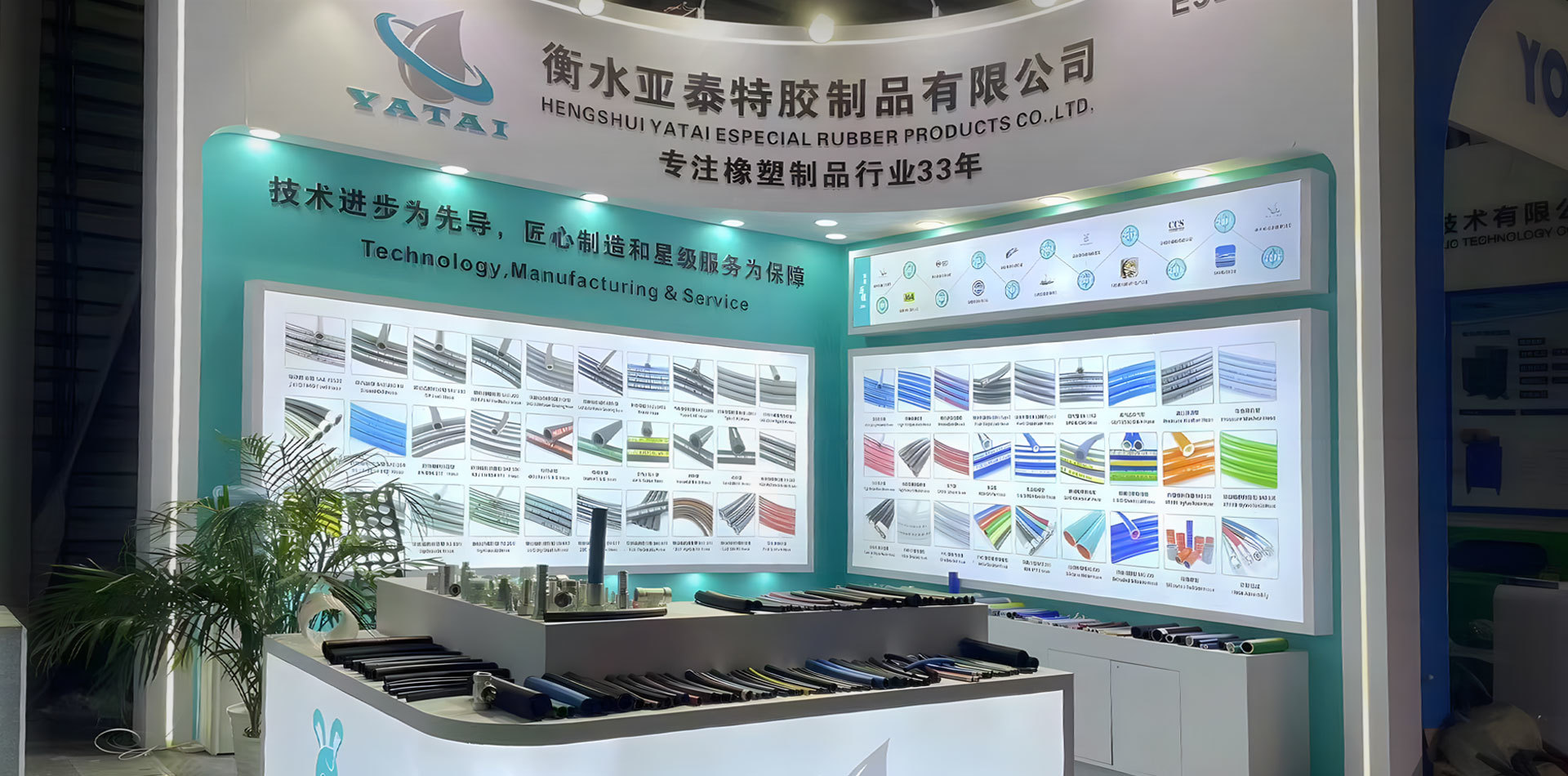

Hengshui yatai rubber products co., ltd (Hengshui yatai Especial rubber Products co., ltd.) was founded in 2001 and is a professional manufacturer of high-performance rubber hoses.

Performance and Application of High Temperature Steam Hose

In modern industrial production, high temperature steam hose is a very important equipment and has a wide range of applications. It can not only transport high-temperature steam, but also withstand high pressure and wear resistance, so it has been widely used in many industrial sites.